Understanding Different 3D Printing Technologies

“Understanding the differences between FDM, SLA, SLS, DLP, MJF and EBM will help you make decisions.”

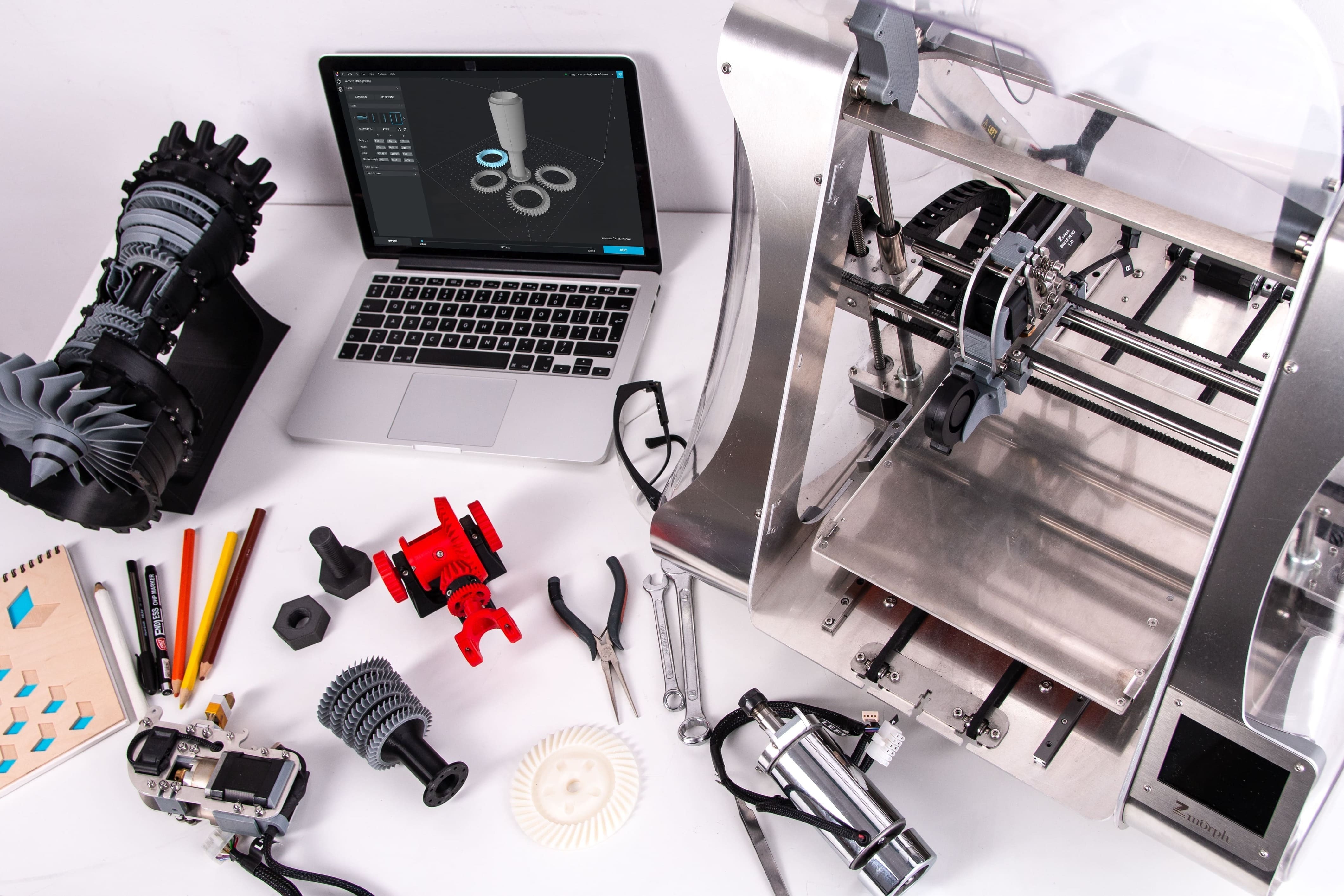

3D printing has evolved rapidly, and today there are various technologies that offer solutions for a wide range of applications. Understanding the differences between these technologies is essential to choosing the most appropriate one based on your specific needs. In this article, we will explore some of the most common 3D printing technologies, their fundamental principles, and typical applications of each.

1. Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) technology is one of the most popular and accessible. In this process, a thermoplastic filament is melted and deposited layer by layer to build the three-dimensional object. FDM 3D printers are widely used due to their affordability and versatility. They are applied in the creation of prototypes, end-use parts and educational projects.

2. Stereolithography (SLA)

Stereolithography (SLA) uses an ultraviolet laser to solidify layers of liquid photosensitive resin. This process produces models with high resolution and fine details. SLA 3D printers are ideal for creating detailed prototypes, jewelry, and high-precision components in fields such as dentistry and medicine.

3. Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) technology uses a laser to fuse material powder particles, such as polyamide or metal powder, layer by layer. This method is known for its ability to print objects without the need for support structures, making it suitable for complex and functional parts. SLS printers are commonly used in the production of industrial parts and engineering prototypes.

4. Digital Light Processing (DLP)

Similar to SLA, digital light processing (DLP) technology uses projected light to solidify photosensitive resin. The main difference lies in how the light is projected. DLP uses an array of mirrors to project an entire image on a single layer, which can speed up the printing process. This method is used to create accurate and detailed models in applications ranging from dentistry to jewelry.

5. Multi Jet Fusion (MJF)

Multi Jet Fusion (MJF) technology uses fusion agents and a powder agent to create layers of material. A printing carriage applies a uniform layer of powder, while a fusing agent and detailing agent are used to solidify specific areas. This technology is known for its speed and precision, being used in the production of prototypes and final parts for various industries.

6. Electron Beam Melting (EBM)

Electron beam melting (EBM) uses an electron beam instead of a laser to melt metal powder. This method is especially suitable for printing metallic objects and is used in the production of engineering parts, medical implants and aerospace components. EBM allows the manufacturing of highly resistant and complex metal parts.

Conclusion

3D printing offers a variety of technologies, each with its own unique characteristics and applications. Whether you're interested in rapid prototyping, detailed parts, or finished products, choosing the right technology is crucial. Understanding the differences between FDM, SLA, SLS, DLP, MJF and EBM will help you make informed decisions and take full advantage of the capabilities of 3D printing.