Innovative Materials for 3D Printing: Beyond Plastic

“The evolution of 3D printing materials is significantly expanding the possibilities of this technology.”

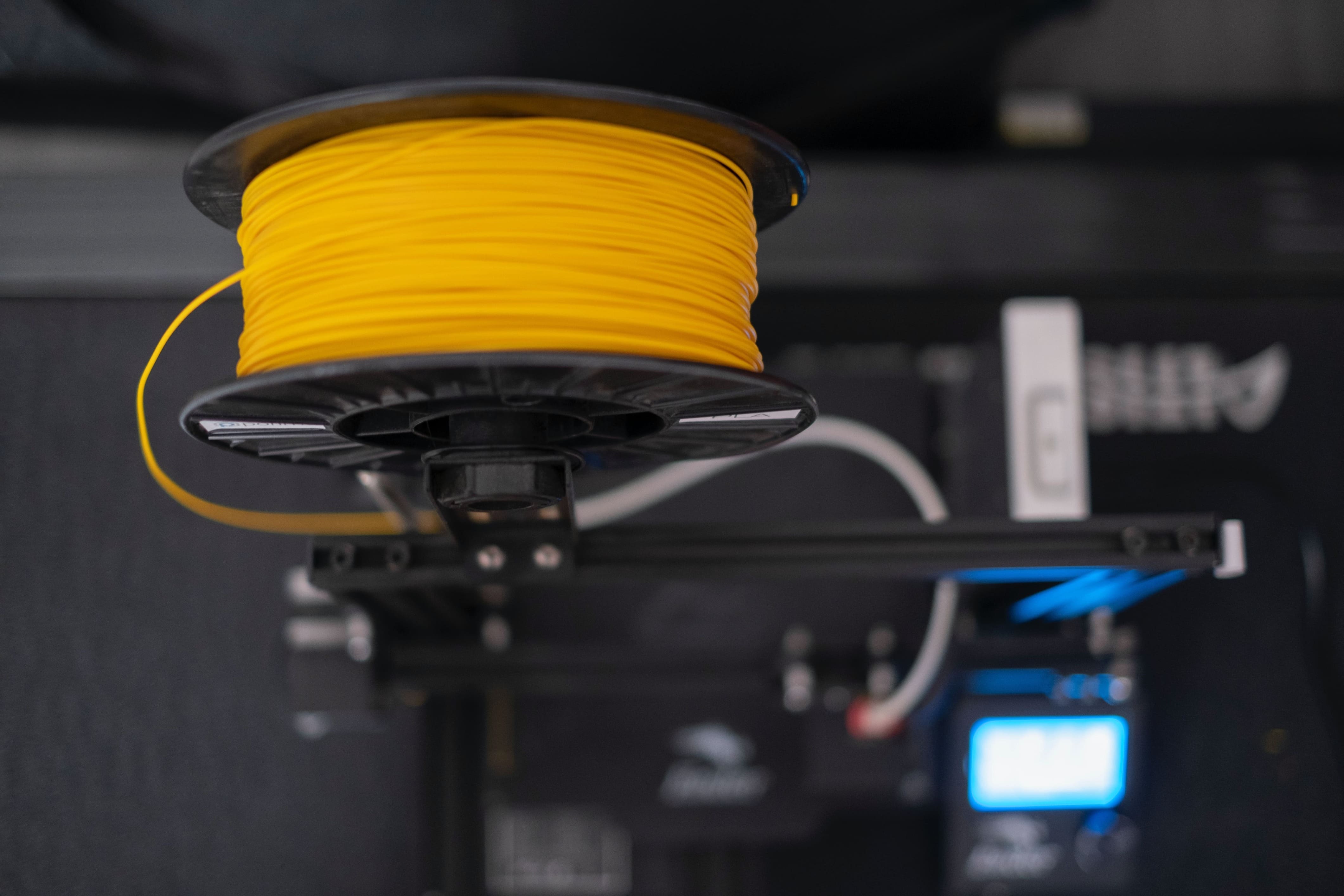

3D printing has evolved significantly since its inception, and one of the most exciting aspects of this technology is the diversity of materials that can be used. Beyond conventional plastics, developers have explored and created innovative materials that open up new possibilities in terms of strength, flexibility and applications. In this article, we will explore some of these materials that are taking 3D printing to new heights.

1. Metals

Metal 3D printing has revolutionized the manufacturing of metal parts. Titanium, stainless steel and aluminum alloys can be 3D printed, allowing the creation of strong and durable structural components. These materials are ideal for aerospace, medical and engineering applications.

2. Ceramic

Ceramic 3D printing has found its place in the manufacturing of complex and customized ceramic parts. This material is used in the creation of decorative objects, dental pieces and high temperature components. The ability to print ceramics opens up new possibilities in designing products with specific properties.

3. Bioplastics

Bioplastics derived from renewable sources, such as corn starch and sugar cane, are a more sustainable alternative to traditional plastics. These materials are biodegradable and are used in 3D printing for applications ranging from packaging to medical products. The search for environmentally friendly options drives innovation in this field.

4. Conductive Materials

3D printing conductive materials, such as conductive filaments and special inks, allows the creation of electronic components directly integrated into 3D printed objects. This is especially valuable in the manufacturing of custom electronic devices and prototypes.

5. Composites Filaments

Composite filaments combine polymers with reinforcing particles such as fiberglass, carbon or metal. These materials offer a unique combination of strength and lightness, making them ideal for applications where durability is required without sacrificing weight. Composite filaments are common in the manufacture of engineering and sports parts.

6. Printed Concrete

3D printing of concrete structures is an innovation in construction. Large 3D printers can build complex walls and structures efficiently. This approach has the potential to transform the construction industry, enabling the rapid and cost-effective creation of customized and sustainable buildings.

Conclusion, the evolution of 3D printing materials is significantly expanding the possibilities of this technology. From metals to bioplastics to conductive materials, the diversity of options allows designers and manufacturers to address a variety of challenges and create more personalized and sustainable products. As research and development continues, we can expect to see even more innovations in the fascinating world of 3D printing materials.