How to Solve Common 3D Printing Problems

“Fixing common 3D printing problems requires a systematic and careful approach”

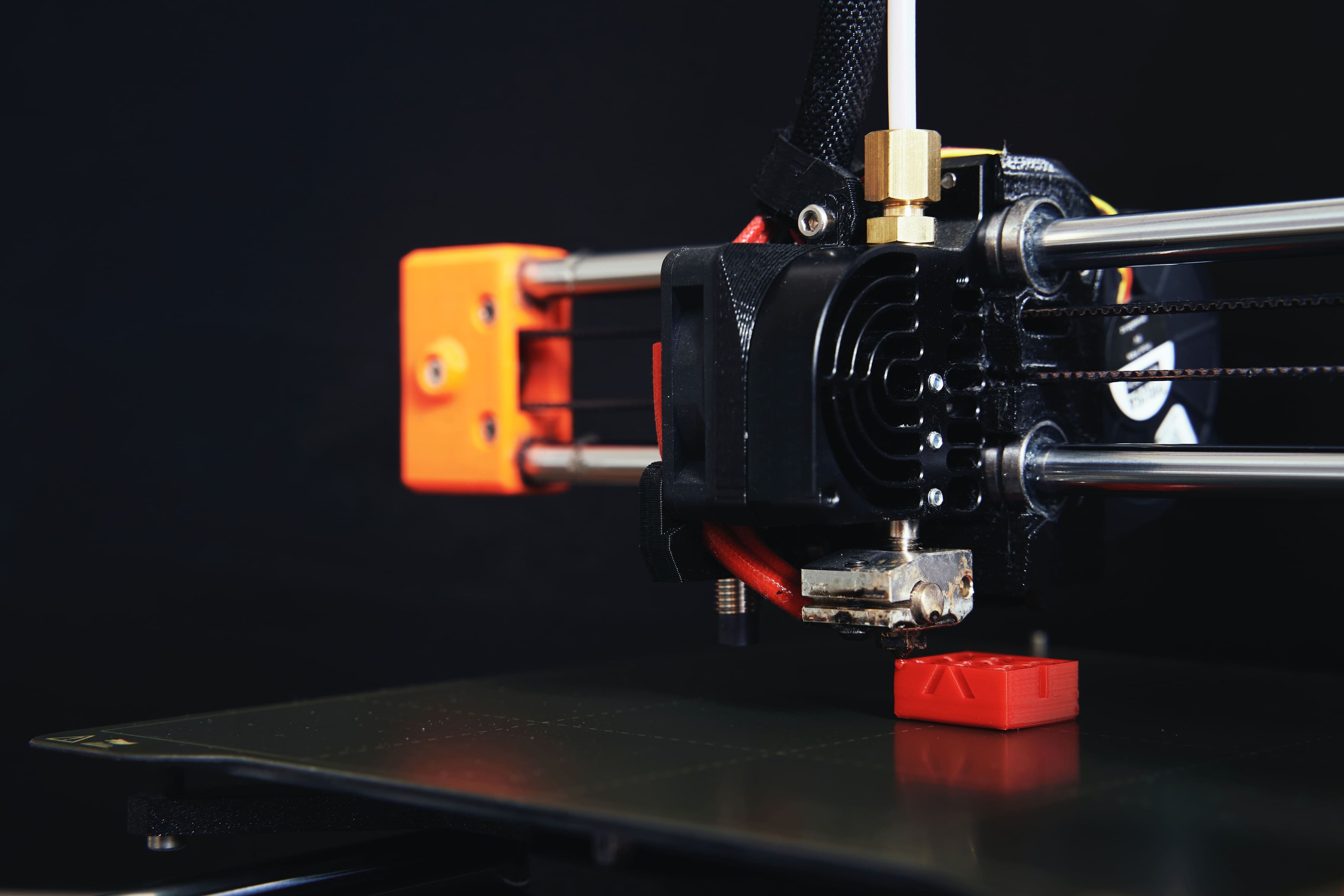

3D printing is a fascinating technology, but like any process, it can encounter various challenges. From poorly adhering layers to bed leveling issues, 3D printer users often face obstacles. In this article, we will explore solutions for some common 3D printing problems to help you achieve optimal results in your projects.

1. Layers that do not adhere

If the layers of your print are not adhering correctly, check the leveling of the bed. Make sure the distance between the nozzle and the bed is uniform at all points. Also, confirm that the bed is clean and applied with a suitable adhesive, such as hairspray or 3D printing tape.

2. Warping or Edge Deformation

Warping occurs when the edges of your print rise during processing. To fix this, make sure the bed is at the correct temperature and that the print is being cooled evenly. Additionally, consider using a heated printing surface and properly use the brim or raft to improve adhesion.

3. Irregular Extrusion or Nozzle Blockages

If you experience uneven extrusion problems or nozzle blockages, check the quality of the filament and make sure it is inserted correctly. Clean the nozzle if there is any residue and adjust the extrusion temperature according to the filament manufacturer's recommendations. Also, consider checking the print speed and extruder pressure.

4. Rough or Irregular Printing Surface

A rough print surface can be caused by poor bed leveling, excessive distance between the nozzle and the bed, or problems with the first layer. Adjust the leveling, check the distance, and make sure the first layer is an appropriate height. Also, confirm that the printing surface is clean and free of obstructions.

5. Small Details Not Printing Correctly

For small details, adjust the print speed and temperature. Make sure the nozzle is clean and unclogged, and consider using a smaller nozzle if necessary. Also, check if your 3D model has enough resolution and detail to be printed correctly at the scale you have chosen.

6. Adhesion Problems between Layers

If you experience adhesion problems between layers, adjust the printing temperature to ensure proper fusion between the layers. Additionally, consider using a slower print speed and ensure uniform cooling to avoid sudden temperature differences between successive layers.

In short, solving common 3D printing problems requires a systematic and careful approach. From bed leveling to adjustments in temperature and print speed, addressing these issues will allow you to achieve more consistent and satisfying results in your 3D printing projects. Remember to adjust the parameters according to your specific printer and filament.