3D Printing and Robotics: Combining Technologies to Innovate

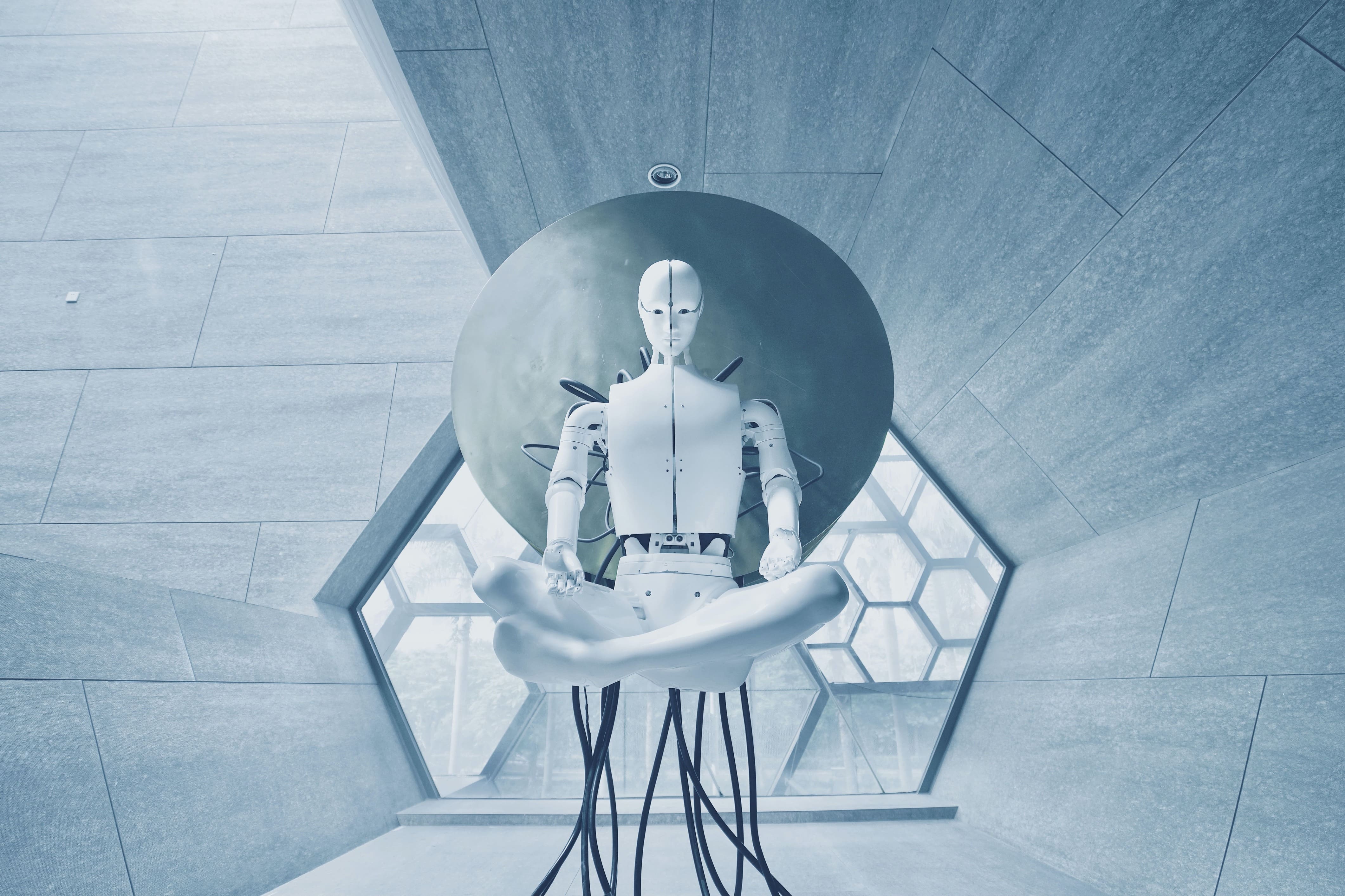

“The combination of 3D printing and robotics is transforming the future of robotics, enabling significant advances in design, customization and rapid prototyping”

The fusion of 3D printing and robotics has generated significant advances in various fields, from prototyping to the creation of advanced robots. In this article, we will explore how the combination of these two technologies is driving innovation and opening up new possibilities in the world of robotics.

1. Rapid and Iterative Prototyping

3D printing allows for the rapid and economical creation of prototypes, which is essential in the development of robots. Engineers can design components, 3D print them, and iteratively test different designs. This capability accelerates the robot development process, allowing for continuous adjustments and improvements.

2. Component Customization

Robotics often require specific, customized components to suit different applications. 3D printing makes it easy to customize parts and components to the exact needs of the robot. This translates into more efficient and specialized robots for specific tasks.

3. Integration of Light Structures

3D printing allows the creation of lightweight and complex structures that are difficult to achieve with traditional manufacturing methods. By incorporating 3D printed components, robots can benefit from lighter structures without compromising strength, resulting in more agile and efficient robots.

4. Integrated Sensors and Custom Housings

3D printing makes it easier to integrate sensors directly into the structure of robots. Designers can print custom housings that precisely house sensors. This seamless integration improves the aesthetics and functionality of the robots, in addition to allowing the creation of robots with advanced sensory capabilities.

5. Development of Robotic Limbs

In creating robotic limbs, 3D printing is especially beneficial. Designers can print biomimetic structures that mimic human or other animal anatomy. This opens new possibilities in creating robots with more natural movements and adapted to specific environments.

6. Manufacturing of Strong and Durable Cases

3D printing allows the manufacture of strong and durable casings to protect the internal components of robots. Materials such as ABS and polycarbonate provide impact resistance and durability. This is crucial for robots used in harsh environments or industrial applications.

7. Education and Development of Prototypes in Robotics

The combination of 3D printing and robotics has facilitated education and prototype development in the field of robotics. Educational institutions can use 3D printers to teach robot design concepts and allow students to create prototypes quickly and affordably.

8. Advances in Service Robotics

In the field of service robotics, 3D printing has contributed to the creation of more accessible and adaptable robots. Robots can be customized to meet the specific needs of various industries, from healthcare to logistics, driving the adoption of robots in real-world environments.

Conclusions: Transforming the Future of Robotics

The combination of 3D printing and robotics is transforming the future of robotics, enabling significant advances in design, customization and rapid prototyping. This synergy between technologies opens new possibilities and contributes to the development of more efficient and adaptable robots in various applications and sectors.