3D Printing and Development of Electronic Components

“ Technological advances: 3D printing and development of electronic components to improve the production and creation of objects.”

Introduction to 3D printing and its relationship with the development of electronic components

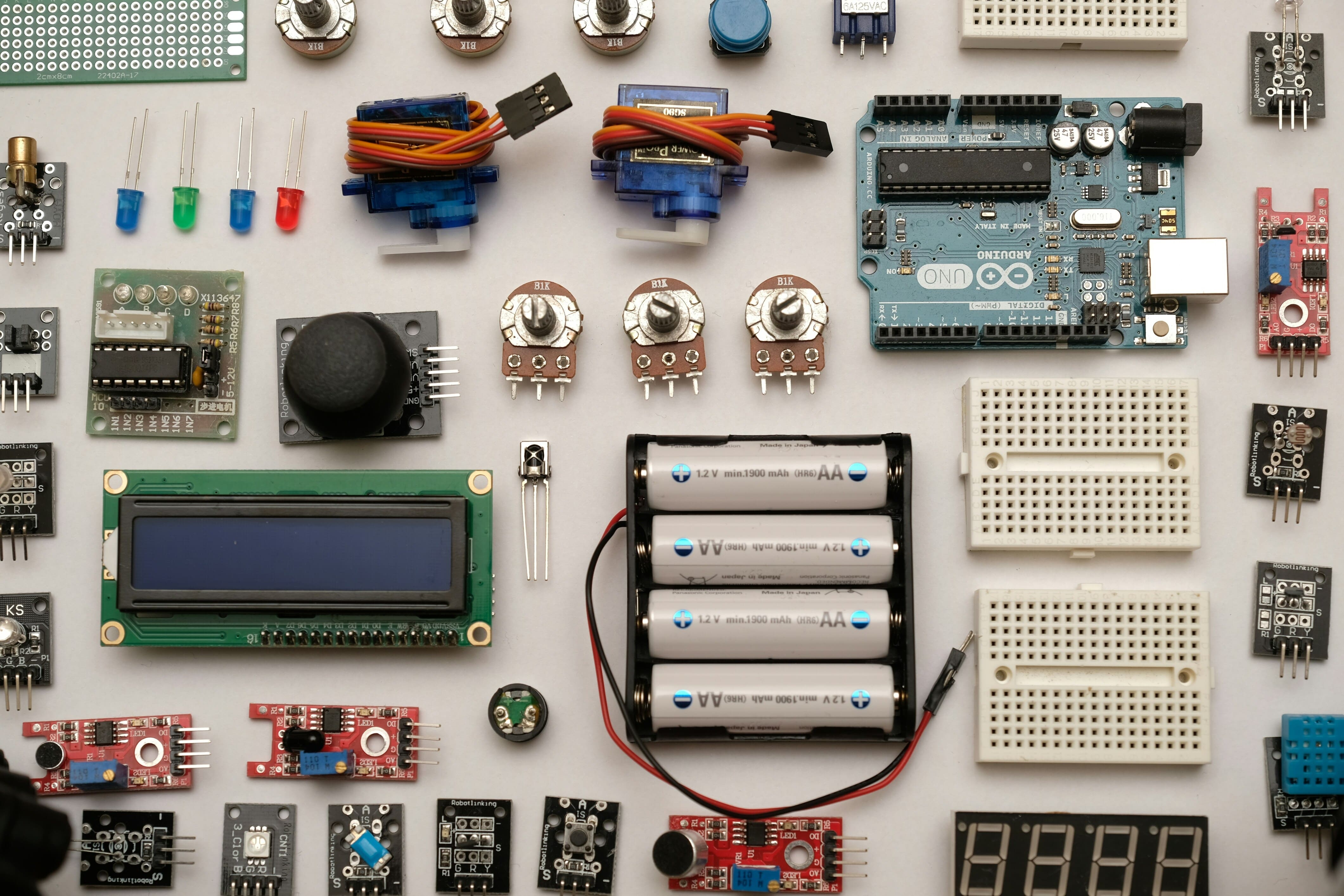

3D printing has revolutionized the way a wide range of products are designed and manufactured, from prototypes to final parts. This technique allows you to create three-dimensional objects from a digital model using materials such as plastic, resins, metals, among others. As technology has advanced, 3D printing has been used in various industries, including electronics. In this article, we will explore the connection between 3D printing and the development of electronic components.

The impact of 3D printing on the electronics industry

3D printing has allowed manufacturers to create electronic components with greater precision and efficiency than traditional manufacturing methods. This has led to an improvement in the quality and performance of electronic products. Additionally, 3D printing has significantly reduced production costs, making it more accessible to businesses of any size.

Another advantage of 3D printing in the electronics industry is the possibility of creating custom designs and prototypes quickly and economically. Engineers can create custom electronic components to meet the specific needs of a project, allowing for greater flexibility in design and optimization in the functionality of the final product.

In addition, 3D printing has also driven innovation in the field of electronics. With this technology, engineers can experiment with different designs and materials more quickly and at a lower cost, which has led to the development of new electronic components and products that would not have been possible with traditional manufacturing methods.

3D printing applied to the development of electronic components

3D printing has been used in various stages of the electronic component development process. In the design phase, this technology allows engineers to create scale prototypes to test the functionality of the design and make modifications before moving to mass production.

Once the design has been completed, 3D printing can be used to produce the actual components. This includes everything from simple items, such as covers and project supports, to more complex parts, such as printed circuit boards and electronic device casings.

Additionally, 3D printing has allowed engineers to create electronic components with shapes and sizes that were previously difficult or impossible to produce. For example, traditional printed circuit manufacturing involved the use of flat plates, while with 3D printing, circuits can be created in different shapes and dimensions that better fit the final devices.

Challenges and limitations of 3D printing in the development of electronic components

Despite its numerous advantages, 3D printing also presents some challenges and limitations in its application in the electronics industry. One of them is the availability of suitable materials for the manufacture of electronic components. Although technology has advanced, there is still not a wide range of materials compatible with 3D printing that offer the same properties as materials used in the traditional manufacturing of electronic components.

Another challenge is the precision of 3D printing. Although 3D printers have improved in terms of resolution and tolerance, they still cannot match the precision of traditional manufacturing methods such as plastic injection or laser engraving.

Additionally, the quality and reliability of 3D printed electronic components are not yet fully tested and may vary from supplier to supplier. This raises concerns regarding the safety and reliability of the final products.

Conclusions

In summary, 3D printing has had a significant impact on the electronics industry, from prototyping to mass production of components. This technology has enabled greater precision, flexibility and efficiency in the development process, which has led to an improvement in the quality and performance of electronic products. However, there are still challenges and limitations in the application of 3D printing in the electronics industry, requiring continued focus on research and development to improve the technology and expand its possibilities in this field.